For many field developments and challenging export and transportation system projects, the pipelines play a vital link and can have a large impact on the feasibility and practicality of the project. PERITUS has in-depth knowledge and extensive experience in dealing with the most complex pipeline design, installation, operation and decommissioning problems.

Typically, the pipeline work undertaken by PERITUS covers all design engineering phases and can be described broadly by the following activities:

Within a typical pipeline design the following elements are normally required, the level of work required depends on both the stage of the project whether concept selection through to detailed design or the environment and type of product:

- Pipeline sizing, wall thickness and steel grade

- Pipeline route selection

- Stability analysis, weight coat and/or trenching

- Bottom roughness assessment including spanning analysis

- Pipeline installation assessment

- Material Selection and Specifications

- Landfall design

- Tie-in design (risers and subsea facilities)

In addition and/or based on the findings above some aspects of pipeline design can require a more detailed investigation such as:

- Buckling assessment

- Geohazard Analysis

- Risk study considering other external influences and definition of remedial measures

Peritus assists Clients in the development of EPIC documentation such as:

- Invitation to Bid (ITB) Documents

- Materials, fabrication and Construction Specifications

The Peritus vision is for us to perform projects located in remote, hostile and deepwater environments. To achieve this Peritus has developed capabilities and a team of experienced people in a global network who have dealt with all types of pipeline design:

Within the Peritus organisation the pipelines team capabilities include:

- Wall Thickness Sizing

- Material Selection

- Design Code and Acceptance Criteria

- Cathodic Protection Design

- Freespan Design

- Expansion

- Bottom Roughness

- Routing

- Spool Piece Design

- HP/HT Design

- Pipe – Soil interaction

- Lateral Buckling Design, Mitigation and Operation

- Upheaval Buckling Design and Mitigation

- Walking Design, Operation and Mitigation

- Geohazard pipeline interaction

- Flexible pipelines

- Conventional Steel Risers

- Bundle Design

- Landfall Design

- Bulkhead Design

- J-lay Collar Design

- Buckle Arrestor Design

- Slugging Design

- Ice Interaction

- Engineering Criticality Assessment

- Reliability

- Specification Preparation

- Cost Estimation

- Installation Procedures and Manuals Preparation

- Operation and Maintenance Procedures and Manuals Preparation

- Emergency Procedures manuals

- Pipeline Decommissioning, Abandonment and Recovery Design

- Installation and construction Hazard identification

Wall Thickness Sizing

With there being a large number of internationally recognised codes, Peritus has offices in the major offshore centres of the world, all with experienced people within the pipelines field so the selection and use of appropriate codes and optimisation of wall thickness is well understood and can confidently be dealt with.

Material Selection

Experience has been gained working on projects located in extreme environments such as the arctic, Caspian Sea, Sakhalin Island as well as in ultra deep water and estuaries. Material has been specified for sour and sweet service as well as high temperature (130°C) and pressures (900barg).

The impact of material on installation options, costs, weldability, corrosion protection, frictional resistance, impact, compressibility and elongation has also been investigated during concept selection, FEED and through to Detailed design and offshore inspection and support.

Carbon steel, corrosion resistant alloys (CRA), metallurgically bonded (clad) and CRA-lined linepipe, duplex, super duplex, 9% Ni steels all behave differently, have different values of toughness and likely crack growth rates which impact the ECA and all have different influences on other design aspects such as expansion, buckling and cathodic protection and as such require a thorough understanding of where it is best /essential to use these and where it is recommended to avoid using such materials.

Design Code and Acceptance Criteria

Our global reach means we have an in depth understanding of all internationally recognised codes and can assist Clients with code selection for areas where local regulations do not dictate.

There have been occasions where it has been necessary to either go beyond the guidance presented within the code or to investigate a solution outside of the scope of the codes guidance, within this field Peritus employees have both investigated and proposed solutions which have been reviewed and approved by independent 3rd parties / code verification bodies or have acted as 3rd party verification bodies to aid another company with finding a solution to a given problem.

Routing

Having experience in installing pipelines, spools and structures in water depths in excess of 2000m where accuracy and weight are key issues, or installing pipelines up and down escarpments with multiple fault lines and mudslides where having a detailed understanding of how these features interact with the pipeline and what the maximum slopes the vessel is capable of installing on. Having a thorough understanding of the environment, how the environment will interact with the pipeline, the installation vessel,

External Corrosion Protection Design

Below 80°C the standard design codes and commonly used methods provide good protection solutions for pipelines, however above 80°C the standard coatings and anode solutions require more advanced design solutions and sometimes additional requirements such as pipeline cooling need to be considered and therefore the coatings must aid this.

Freespan Design

Over recent years optimising the allowable span lengths to aid with installation and also to review an already operating pipeline has become something with which Peritus are entirely familiar.

Optimisation of the allowable span length taking into account additional factors such as slugging, cyclic loading (i.e. start-up and shut-down cycles), structural interaction, environmental and accidental loading are all items with which Peritus employees have gained detailed experience.

Peritus employees’ experience is not limited to just the design phase: offshore real-time span analysis and acceptance or rectification work has been performed both during installation and during the operation of pipelines round the world.

Operational pipelines located in areas of moving seabed features such as sand waves or in areas prone to cyclone or typhoon environmental loading have also been investigated and solutions found to allow for the minimum amount of intervention to be performed so as to not impact the operation of the pipeline has also been performed.

Expansion

Sliding bundle and pipe in pipe systems where by the different pipes expand at different rates can cause a problem for bulkheads and internal fittings is another area where Peritus employees have an excellent understanding and have performed numerous detailed designs.

Bottom Roughness

With the use of either general finite element packages such as Ansys and Abaqus or special purpose bottom roughness packages such as SAGE® and SIMLA® either a 2D seabed profile or the full 3D seabed where the pipeline is planned to be installed can be modelled and it is possible to predict where the pipeline is prone to excessively long or highly stressed spans. For long spans a fatigue analysis can be performed and, if the total amount of fatigue is less than the allowable, then the spans can remain, however if the spans exceed the allowable fatigue limit and/or are over stressed then different mitigation methods can be investigated and analysed within the packages in order to determine the best solution for the pipeline.

Bottom roughness analysis can also feed into the lateral buckling and walking assessment as natural seabed features can act as buckle initiators or the seabed influence expansion and walking due to slopes.

Spool Piece Design

From shallow water large diameter conventional “Z” shaped spools to complex 140m long 3D spools located in 2200m water depth as well as jumpers all have been designed as part of previous experience. The material selection, connection selection, contents, pressure, temperature, expansion and installation limitations are some of the key parameters with which need to be accounted for when investigating the design of spool pieces

Conventional Steel Pipe Risers

Riser design involves routing from the platform topsides tie in point to the pipeline/spool tie in point on the seabed. The analyses include vortex-shedding analysis to determine maximum allowable riser span lengths/clamp spacing at given elevations above the seabed; fatigue analysis to investigate the possibility of failure for the proposed span length and detailed stress analysis of the riser and pipeline offset including functional and environmental loading and also for platform jacket deflections.

HP/HT Design

New developments are always being found which have high pressures and/or high temperatures, these in combination with severe contents can cause complications for designers. High pressure (>900bar) and high temperature (>130°C) are values with which Peritus employees have experience and has investigated solutions for. The material selection process for such extremes has been found to be critical along with the design approach adopted. Depending on location, water depth and environmental conditions the solutions can be radically different however the outcome is always for a safe and robust design.

Pipe – Soil interaction

Accounting for the small amount of compressibility within the soil upheaval buckling prior to the pipe forcing its way through the soil has been shown to improve the predicted behaviour of the pipelines and this can now be modelled within finite element packages.

For pipelines resting on the seabed accurately modelling the axial friction resistance of the soil is essential in predicting expansion and force build up within the flowline as well as the probability of the pipeline walking should it experience multiple thermal cycles.

Accurate modelling within finite element packages of these phenomena is critical to producing a robust design which is not either over conservative or impractical for the location in which it is being used.

Upheaval and Lateral Buckling Design, Mitigation and Operation

Lateral and upheaval buckling can become one of the major design challenges within a pipeline project and needs to be identified early on so that work can commence on finding the best solution for that given pipeline.

In recent years there have been major developments within finite element modelling of upheaval and lateral buckling and the solutions to either mitigate buckling or control lateral buckling. Conventional methods of preventing pipelines from lateral buckling such as rock dumping and multiple inline expansion spools are often not practical due to location and environment issues such as deep water and vessel availability

Peritus employees pride themselves in having worked on a number of very complex projects where different and detailed lateral and upheaval buckling solutions have been required.

Walking Design, Operation and Mitigation

Walking analysis screening and detailed finite element analysis have all been performed by Peritus employees. Both transient thermal induced walking and gravitational walking in shallow and deep water have been investigated along with how walking interacts with structures, spools and pipeline buckles. Where required, various walking mitigation solutions have been investigated and practical solutions found to solve the problem.

Bundle Design

Peritus employees have a large amount of experience with the design, fabrication and installation of bundles within the North Sea.

Additional experience has been gained investigating the use of bundles within directional drilling scenarios, high temperature/ultra high pressure and ice/arctic environments.

Landfall Design

From basic pre-feed investigations and high level cost estimates through to detailed finite element modelling of the pipeline taking into account earthquake loading, crossings and pressures and temperatures Peritus Employees have handled the design and produced reports and drawings required for either the next phase of the work of for construction.

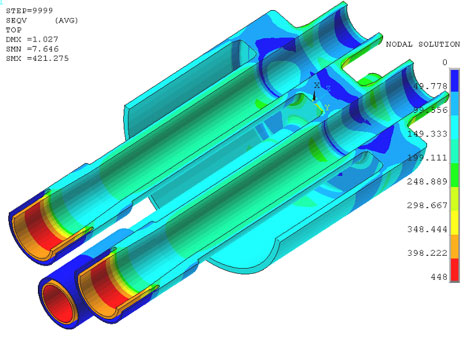

Bulkhead Design

Peritus employees have been involved with the design and procurement of both bundle and pipe-in-pipe bulkheads. In addition to performing detailed finite element analysis to design the bulkheads additional analysis has been performed to model the as built material properties of the bulkhead forgings which different slightly from the adjacent linepipe. Two approaches have been adopted for investigating how the actual bulkhead is likely to perform within a buckle, the first involved applying the anticipated forces and moments expected at the crown of a buckle to a short section of linepipe containing the bulkhead and the second involved placing the forging within the global finite element model to investigate how the system would respond with the introduction of bulkhead having different properties to the linepipe.

Buckle Arrestor Design

Peritus employees have design pipeline systems with either short ring type buckle arrestors or longer thick wall line pipe buckle arrestors. As part of their design approach, the use of buckle arrestors as J-lay collars has been included as well as investigation into the optimum spacing of buckle arrestors as part of a cost versus probability analysis. In a similar manner as with the bulkheads, Peritus employees have performed detailed finite element analysis to investigate the impact of these forgings being present where the pipeline is prone to lateral buckling. Detailed dynamic finite element analysis to model and confirm that the buckle arrestor stops propagation buckling from passing through buckle arrestors has also been performed.

J-lay Collar Design

Peritus employees have been involved with the design of J-lay collars which have been used as both j-lay collars and buckle arrestors and have performed detailed finite element analysis to ensure that these collars are capable of withstanding all loads to which they will be exposed.

In addition to standard J-lay collars Peritus employees have experience in analysing small stiffener rings which have been used for the same purpose as J-lay collars but are installed on the inner pipe in a pipe in pipe system. These collars were required to hold the inner pipe out of the outer pipe during the installation of bulkheads to a pipe in pipe system. In addition to these forgings being modelled during the installation process they remain in the system and so were included within the lateral buckling investigation in a similar manner to the bulkhead and buckle arrestors.

Slugging Design

By combining the slugging effect in to bottom roughness, lateral buckling and spoolpiece analysis Peritus employees have gained a detailed understanding of the effect of slugging on pipelines as well as different methods and techniques for preventing excessive damage to the pipeline system.

Ice Interaction

With oil and gas being found in remote areas of the world where ice is present either all year round or during the winter there are some key additional analysis which need to be investigated and where possible either routed around or avoided by burial.

- Strudel Scour – Strudel scour forms when ice melts and rivers of water create a hole in the ice where the water flows down into an under-ice river. The water, as it moves downwards, has significant velocity and therefore the ability to erode away large sections of the seabed.

- Stamuka – Stamuka or ice ridges are one of the more complex ice phenomena as they are made up of crushed blocks of ice and therefore understanding their density and its interaction with the seabed not simple. Stamuka occur where floating ice starts to pile up and comes into contact with the seabed, some stamuka have been recorded at approximately 20m in height and as such can apply a large force downwards onto the soil, this can either directly displace the pipe downwards if it is located on the stamuka and/or move the pipeline sideways if located near to the pipeline.

- Iceberg scour forms another major area for pipeline design and like stamuka requires detailed investigation into area specific phenomenon. Shore/Island approaches is another area where innovative solutions are required as ice tends to pile up at the shore line or on the defences round an island and therefore conventional shore approaches are not always practical and possible. Frost and Thaw is more of a problem for onshore pipelines, however in some of the shallow offshore and short onshore sections which can be associated with offshore pipeline design this annual cyclic even can with time have an adverse effect on the pipeline system as the soil properties change over time and the influence of the pipeline on the surround soil with time can weaken the surrounding soil leading to events like upheaval buckling.

Peritus employees have worked on all aspects of pipeline/ice interaction and have performed both reliability/probability based analysis and as well as detailed pipe-soil and soil-ice interaction analysis.

Geohazard Assessment

Surface fault movements can have serious consequences on pipelines which cross them. Normal and reverse faults introduce spans which will need to be investigated and compared to allowable, however it is the strike-slip faults that require special attention as the fault plates move they can compress the pipeline and in a similar way to lateral buckling the compressive force must be released some way, therefore the pipeline appears to buckle, this problem can be made worse if the earthquake is an oblique slip fault.

In investigating the effect that strike slip faults have on pipelines Peritus employees performed a detailed finite element analysis using both complex friction and a 3D seabed. The analysis calculated the maximum allowable angle over which the pipeline could cross the faults, this in turn allowed for a small amount of rerouting to be performed so that the faults were crossed such that the stresses should the fault occur remain acceptable.

Debris and turbidity flows are triggered when underwater landslides occur and are usually triggered by earthquakes and are made up of the sediment that formed the land slide. Peritus employees have significant experience with debris and turbidity flows having had to route two pipelines down and up seabed slopes with gradients up to 14 degrees. Finite element analysis concluded how near to the bottom of these flows pipelines could be routed as well as calculating how near to the top route curves could be placed to avoid pulling out route bends. The finite element analysis also concluded how far the pipeline would move and what levels of stress would occur in the pipeline.

Probabilistic Seismic Hazard assessment and Fault displacement

Probabilistic fault displacement analysis can be greatly improved if a geophysical survey is performed, this allows for a more accurate understanding of the magnitude and likely trigger mechanism of the faults. Peritus employees have experience in performing fault and geohazard assessments and also have experience with calculating maximum fault magnitudes for given return periods.

Lateral Buckling and Lateral Buckling Related Reliability

Lateral buckling has become a very common challenge for many pipelines performing a reliability-based analysis to determine if the pipeline will buckle, what the likely strength/wall thickness/ovality mismatch at a buckle location is allows for a more realistic design approach. Reliability based design also provides a method of predicting the height, out of straightness, change in weight etc required to initiate buckling.

If buckle initiators such as sleepers or route bends are to be used then being able to calculate what the required height/radius/separation is so that all initiators work and also no rouge seabed buckles form can minimise the number of finite element analysis that need to be performed.

Experience has shown that having actual data for linepipe and forgings early on in the detailed design can greatly reduce the amount of conservatism needed within the design leading to solutions being obtained quicker allowing for engineers to move on to other critical issues.

Specification Preparation

Having specifications that are appropriate and tailored for each individual project is key to getting both value for money and the correct quality of product.

Peritus employees have significant experience in the production of specifications for design, procurement, construction and maintenance for most pipeline projects around the world. With access to highly experienced engineers in different locations being able to pool resources as well as understanding the Client’s needs is a key part of Peritus.

Installation Procedures and Manuals Preparation

Peritus employees have gained experience installing pipelines across the world and have worked as Client representatives offshore, installation contractors and third-party verification bodies, therefore are well placed to write and/or review installation procedures and manuals to ensure that the installation is performed in the safest, quickest and best method.

Operation and Maintenance Procedures and Manuals Preparation

As with the installation procedures and manuals having had personnel who have worked for all the different parties likely to be involved in these operations, Peritus employees are experienced in producing and/or reviewing these documents so that the safest, most efficient, most cost-effective and best solution is available for each specific pipeline and operation.

Pipeline Decommissioning, Abandonment and Recovery Design

As more pipelines and facilities reach the end of their original design life, recovering, abandoning or extending their design life needs to be addressed. Peritus employees have investigated and performed analysis to ensure the integrity of a pipeline which had reached the end of its original design life and have proposed extension periods and inspection programs for the pipelines so that they may remain in operation. Preparing pipelines to be either left in situ as an artificial reef or to be recovered for scrap has also been investigated.

Engineering Criticality Assessment (ECA)

ECA is also commonly referred to as “Fracture Mechanics,” “Fitness-For-Service” or “Structural Integrity.” The main aim of an Engineering Critical Assessment is to determine if pipeline (or component of) is sound enough to meet the service requirements for which it was intended.

Selecting criteria whereby defects within the parent material or weld are either accepted or rejected based on their size, location through thickness, number of or surface interaction. All these factors are calculated/tested and derived from non-destructive tests of the actual material to be welded. Defect interaction rules can be applied to buried defects as well as to defects that may interact with the surface. By combining the stress ranges and fatigue anticipated from detailed finite element analysis for buckling with the defect data it is possible to calculate acceptable flaw sizes or by working with approved acceptable flaw sizes and defect data it is possible to calculate acceptable fatigue and stress ranges.

Peritus employees have performed ECA analysis to the “3” standard levels considered within the major design codes, with detailed investigations into surface/external and embedded defects as well as being involved in preparing scopes and specifications for testing programs and evaluating test results for specific projects.

The primary External Pipeline analysis tools used by PERITUS are:

- DNV PET

- DNV FATFREE

- DNV Stable Lines

- DNV Code Compliance (2000 and 2007)

- Sage 2D

- Sage 3D

- Orcaflex

- Orcalay

- Autopipe

- Cesar

- Mathcad

- MCS Pipelay

- SIMLA

- Geoline 3D

- Fledermaus

- AGA/PRCI Stability

- Crackwise

- Linkpipe

- Solidworks

- Abaqus

- Ansys

- Geocalc

The primary internally created and verified Pipeline analysis tools used by PERITUS are:

- In house Mathcad

- DNV OSF101 (2000 with 2005 amendments) Wall thickness

- DNV OSF101 (2007 amendments) Wall thickness

- BS PD8010 Wall Thickness

- ASME B31.8 and 31.4 wall thickness

- API RP 1111 wall thickness

- DNV OS F101 Linepipe Buckle Arrestors

- Buckle arrestor design as per OMAE2008-57985 L.H. Lee, T.A. Netto and S. Kyriakides

- Buckle Arrestor design as per OTC 10711 Carl G. Langner / Langner & Associates, 1999

- DNV RP F103 Cathodic Protection

- DNV RP B401 Cathodic Protection

- 15589-1 and ISO 15589 Cathodic Protection

- DNV E305 Stability

- DNV GL 13 and RP F111 Trawl Impact

- Linear wave theory selection and velocities

- Lateral buckling in accordance with Hobbs

- Upheaval buckling in accordance with Palmer

- In house FEA software (e.g. based in Ansys / Abaqus)

- Seabed Lateral Buckling

- Seabed Bottom roughness

- Trench Lateral buckling

- Detailed Pipe/soil interaction

- Buried pipe upheaval buckling

- Ice interaction (Stamuka and scour)

- Fishing gear interaction

- Forging design

- Forging/lateral buckling interaction

- Anchor interaction

- Pipeline Impact assessment

- Collapse and collapse prevent (buckle arrestor) analysis

In addition to discipline engineering roles, Peritus can and has provided Project Management Services in the form of provision of owners engineering teams, supervising the EPCIC contractors during Develop and Execute. Peritus are able to use their own management and project support systems if required. Peritus’ Management Systems are certified to ISO 9001.