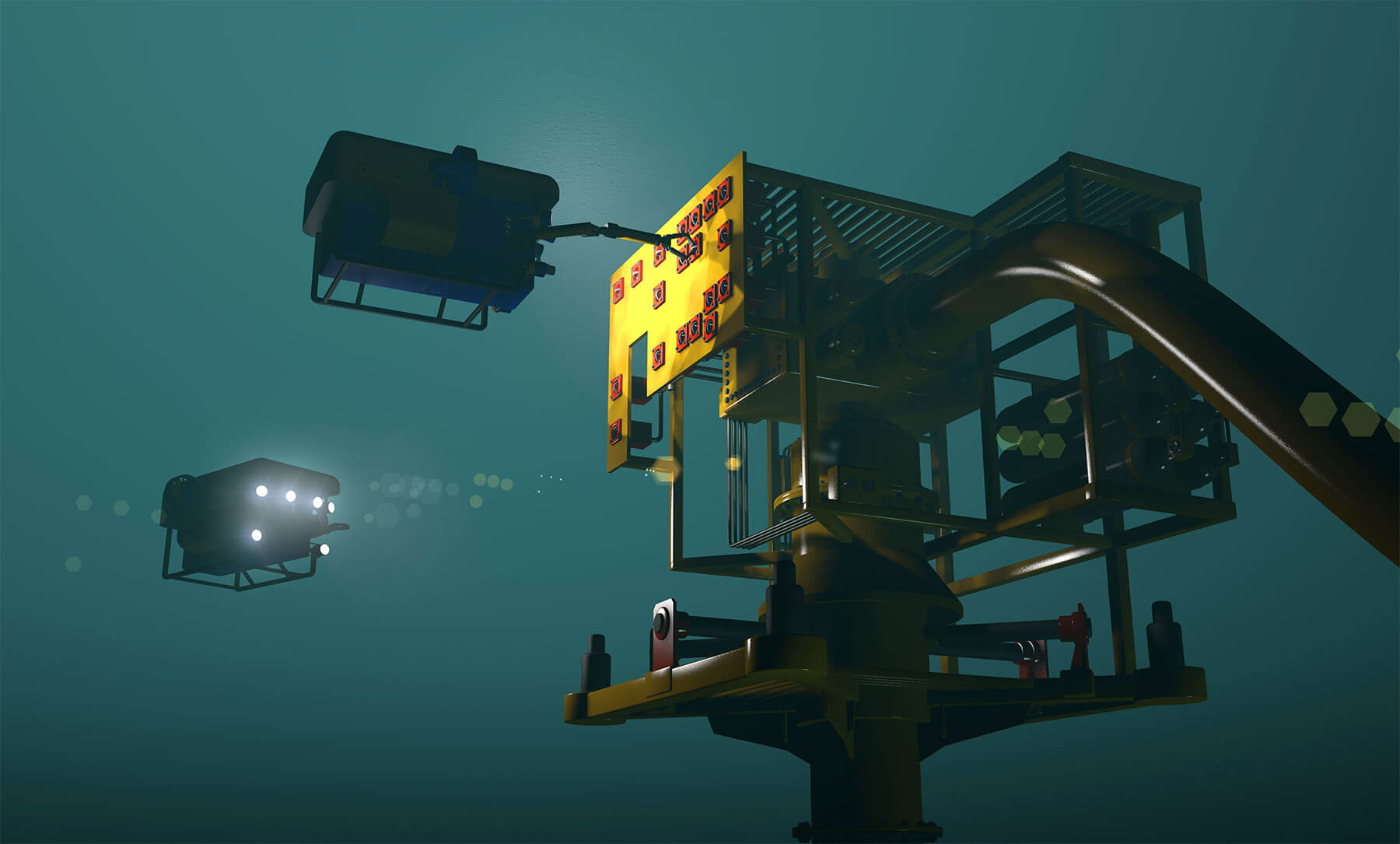

The subsea systems discipline area requires a thorough understanding of the operational requirements to be met through the project lifecycle, and, in turn provides design input for field development planning decisions. The goal is to specify the functional performance requirements of the equipment to be procured from specialist manufacturers and vendors.

The equipment package items are procured as bespoke engineered items forming sub systems from a limited number of specialist vendors based on existing qualified designs. These items are progressively integrated into more comprehensive sub systems that can be tested, delivered and installed by suitable installation contractors. There is only a very limited amount of field fabrication involved, it is more a case of installing, assembling and interconnecting numerous dedicated equipment packages in the subsea field environment.

These dedicated packages are ultimately built up into a subsea production system capable of monitoring and safely controlling the production of hydrocarbons from wells, and delivering streams of hydrocarbons and other fluids to and from pipelines leading to a host facility where any necessary processing can take place. The fluid streams may include varying mixtures of oil, gas, water and various production chemicals which may flow to and from the host facility, to deliver saleable products, to inject water and/or gas back into the reservoir and to dispose of waste streams in the required manner.

The host facility also provides the necessary power and other utilities to enable the subsea system to perform these functions and a location from which these tasks and functions can be remotely controlled and managed by field personnel. The pipelines, and in some cases risers, form essential elements within the overall hydrocarbon production system, but they are generally treated as separate assets due to the significantly different nature of their design and construction.

The host facility may be a fixed or floating offshore structure, or an onshore plant and the length of the pipelines and risers may vary from hundreds of metres to hundreds of kilometres.

General understanding of, and, the ability to engage meaningfully with specialist practitioners in the areas of:

- Hydrocarbon production engineering and production technology;

- Drilling and completions engineering and operations;

- Geotechnical engineering;

- Well installation techniques as performed from drilling rigs;

- Offshore and subsea construction techniques and challenges;

- Offshore and subsea survey and positioning;

- The effects of metocean conditions on offshore construction operations;

- Corrosion and materials engineering;

- Welding and Non Destructive Examination (NDE);

- An understanding of hydrocarbon process engineering and

- The effects of metocean conditions on dynamic offshore structures and risers through the water column from seabed to sea surface.

Peritus’ experienced staff also have sound detailed working knowledge of the following areas:

- Subsea field layout design and understanding of the relevant technical and operational factors that influence it;

- Safe working practices involved with working with high pressures and temperatures, etc;

- Functional requirements of subsea tree and wellhead systems throughout field life, from testing to installation, commissioning, operations, workovers and abandonment;

- Functional requirements of subsea manifolds/Pipeline End Modules (PLEM) /Pipeline End Terminations (PLET) throughout the field life, from testing to installation, commissioning, operations, workovers and abandonment;

- Subsea valves and sealing mechanisms;

- Pressure containment, vessels and piping;

- Hydraulic actuators;

- Electrical power and instrumentation;

- Fluid power and associated power and controls technology;

- Offshore and subsea installation techniques as performed from offshore construction vessels;

- Materials engineering;

- Subsea intervention and inspection (diver assisted and diverless)

- Remote connection technologies for piping, electrical and instrumentation, fibre optic conductors, and hydraulic and chemical high pressure fluid connections;

- Hydraulically powered piping connectors and associated sealing technology (vertical and horizontal orientation)

- Flexible piping systems;

- Rigid steel piping systems;

- Subsea umbilical (hose/tube/power and signal cables/optic fibre) systems;

- Subsea control systems;

- Structural design and fabrication;

- Manufacturing methods, constraints and Quality Control techniques for engineered products in mechanical, electrical, electronic, instrumentation and communications business areas and

- Site management and supervision (onshore/offshore).

Experience has been gained working on projects located in extreme environments such as the West of Shetlands, Arctic, Caspian Sea, Sakhalin Island and in the ultra deep waters of the Gulf of Mexico. Equipment has been specified for sour and sweet service as well as HPHT systems (temperature >130°C and pressure <103 MPa).

Peritus personnel have experience with application of the principal industry codes relevant to design and operation of subsea systems such as:

- API 17/ISO 13628 series of standards and recommended practices;

- API 6A standard;

NORSOK Drilling, Structural and Subsea standards and ASME B31.3

The principal tools required to perform subsea systems work are human and intellectual, such as, technical understanding, experience, skill and the ability to analyse and decide between competing approaches. A number of software tools are available within Peritus to assist the intellectual effort, these being analytical tools and administrative or management tools.

Examples of the analytical tools used by Peritus are as follows:

- SACS – Analysis of steel structures and piles;

- SolidWorks – 3D mechanical design and solid modelling;

- StruCAD – Analysis of steel structures and piles;

- FS2000 – Analysis of steel structures, piles, piping and spools;

- AutoPIPE – Analysis of piping and spools;

- USFOS – Non-linear structural analysis of steel structures, including non-linear pile/soil interaction, with capability for platform pushover analysis;

- SACS COLLAPSE – Non-linear structural analysis of steel structures, including non-linear pile/soil interaction;

- ANSYS – General purpose stress analysis software with temperature, non-linear and dynamic analysis capabilities, utilising stick, plate and solid elements;

- ABAQUS – General purpose finite element stress analysis software with temperature, non-linear and dynamic analysis capabilities, utilising stick, plate and solid elements;

- GRLWEAP – Dynamic pile driving analysis;

- OrcaFlex – Dynamic offshore riser analysis and

- In-house Excel programme for preliminary umbilical design.

In addition to discipline engineering roles, Peritus can and has provided Project Management Services in the form of provision of owners engineering teams, supervising the EPCIC contractors during Develop and Execute. Peritus are able to use their own management and project support systems if required. Peritus’ Management Systems are certified to ISO 9001.